safety assurance

Build your project on the foundation of Morrow quality, trust and service.

SAFETY INSPECTION

Morrow conducts internal safety inspections to assure that a safe and healthful workplace is provided for all employees. In addition, Morrow makes periodic field inspections of fleet equipment. These inspections enable us to provide the highest level of safety and quality of equipment possible. Morrow’s safety programs can provide customers with:

- Resources to monitor and service equipment

- Jobsite safety protocols

- Guidance in safety planning

- Safety inspection forms

SAFETY TRAINING

All of our Morrow service technicians, maintenance personnel, and equipment operators undergo frequent evaluation and are required to maintain NCCCO certification. Morrow service employees continue their safety and inspection education at the worlds leading crane and hoist training facility at Morrow Training Center in Salem, Oregon. Training includes:

- Hazard identification

- Lock-out/tag-out procedures

- Fall protection

- Hazardous communications

- Respiratory protection

- Forklift operation

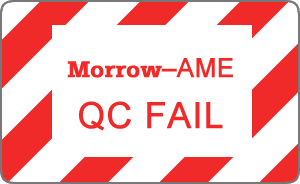

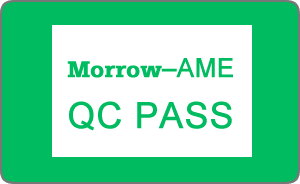

All maintenance, repairs, and inspections are documented by qualified inspectors in each Morrow facility and tracked in our quality control database. In addition, a slewing ring inspection is made on a scheduled basis along with an annual torque check. If all these steps pass our rigorous processes, we are confident the crane will meet the high demands of the customer.

EQUIPMENT CERTIFICATION

Morrow Offers A Complete Range

Of Inspection And Certification Programs. Our Factory-trained Technical Staff And Expert Equipment Inspectors Can Carry Out Any Phase Or Level Of Inspection Required For Tower Crane And Construction Hoist Equipment. From Basic Recommendations For Service And Maintenance To Thorough Testing And Certification, Morrow Will Tailor A Program Meeting Any Customers Need.

With Expert Technical Advise, Dedicated Factory-trained Inspectors And Our Professional Engineering Department, Morrow Provides Each Customer Unparalleled Service In The Certification And Inspection Of Lifting Equipment.